Single screw compressor

Intake pressure: 0.04-6 Bar (A)

Exhaust pressure: ~ 40 Bar (A)

Exhaust temperature: ~100 C

Speed: 1500-3000 r/min

Medium: butadiene, styrene, annular gas, propane, propylene, tail gas,

exhaust gas, torch gas, flash vapor, circulating gas, PSA, CO, CO2

and other petrochemical process gases

Product description

|

The application of single screw compressor was first appeared in the 1970s. Due to its superiority in structural principal, it has advantages like super dynamic balance, no leakage triangular parts, hi-pressure, high performance and good economical feature. And this type of compressor is widely used in petrochemical, shipbuilding, steel mill, power, mining industries.

The technological development of single screw compressor was already quite mature in America and Japan. Single stage discharge pressure of this type single screw compressor has reached over 30 bar in America. Due to increasing demand of this type of compressor in China markets, Haomi Group jointly developed the compressor with some famous domestic universities according to API619 standard for several years. This type of single screw compressor has high compression ratio. Haomi Group overcame core technologies. This single screw compressor filled our technological void in domestic petrochemical fields and reached advanced international level.

|

|

|

Features of single screw compressor

|

|

Features of double- screw compressor

Features of reciprocating compressor

1.Big inertia force when crank shaft rotates, and obvious variances in velocity when piston moves.

2.Small air volume, big displacement margin, low displacement efficiency.

3.Big mechanical loss, frequent change of valve and piston ring. Lots of dismantling and difficult maintenance work.

4.Big vibration, high low-frequent noise. Need special foundation.

|

Features of centrifugal compressor

1、Sensitive to air molecule weight. It has low compression ratio when compresses air with hydrogen. Compression ratio of recycling centrifugal compressor for hydrogen refining is normally below 1.3.

2、High speed rotor, applicable for medium to large capacity conditions, not applicable for small capacity condition.

3、Low efficiency. It can only obtain best efficiency under design condition. This may causes compressor surge.

|

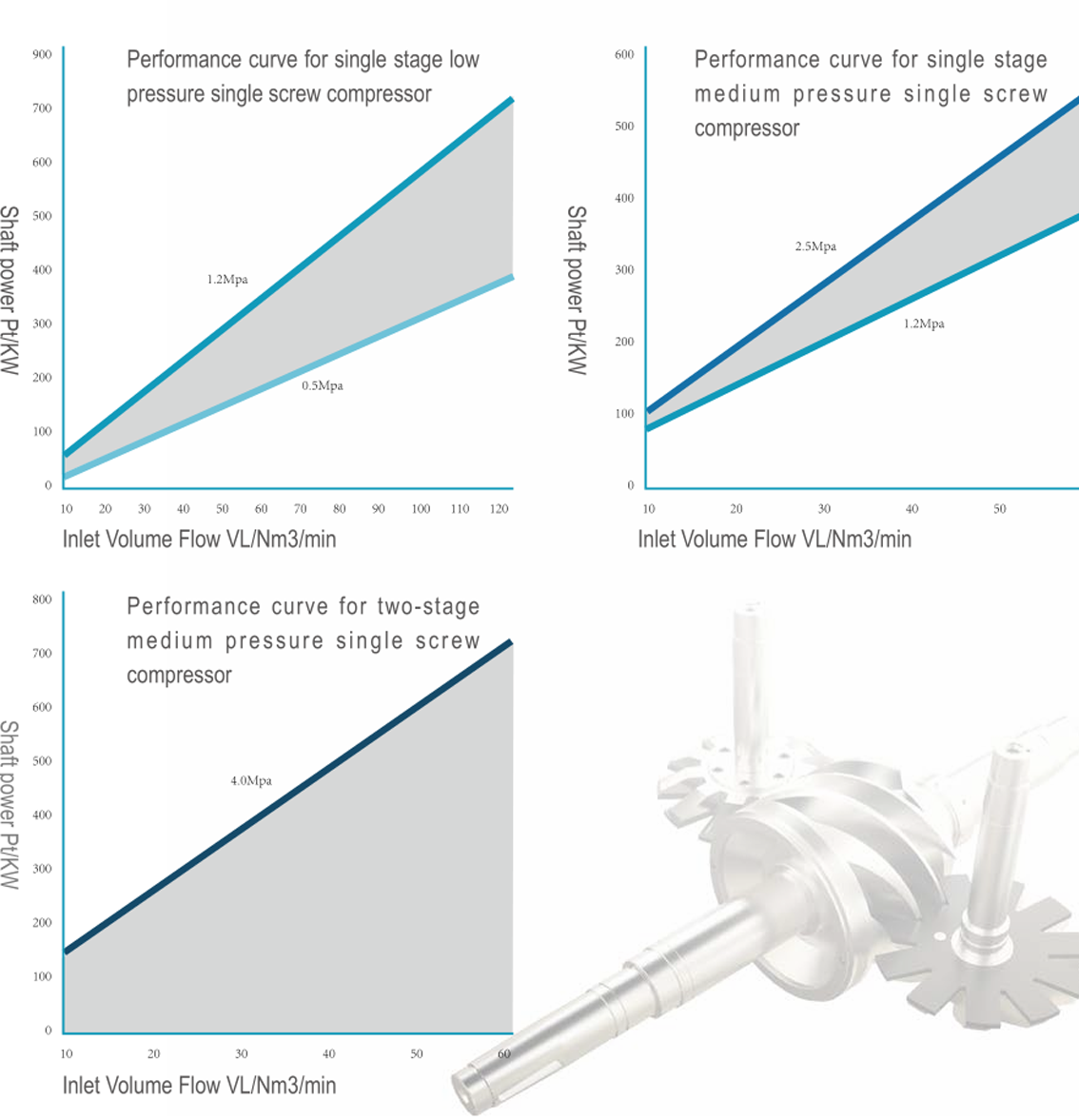

Performance Parameters

| Inlet Volume Flow (m3/min) | Suction Pressure Bar(A) | Max Discharge Pressure Bar(A) | Discharge Temperature(°C) | RPM/min | Medium |

| 10~120 | 0.04~6 | ~40 | ~100℃ | 1500~3000 | Bivinyl, Styrene, Hydrogen cycle gas, Propane, Propylene, Tail gas, Exhaust gas, Flare gas, Flash steam, Cycle gas, PSA, CO, CO2, etc. |

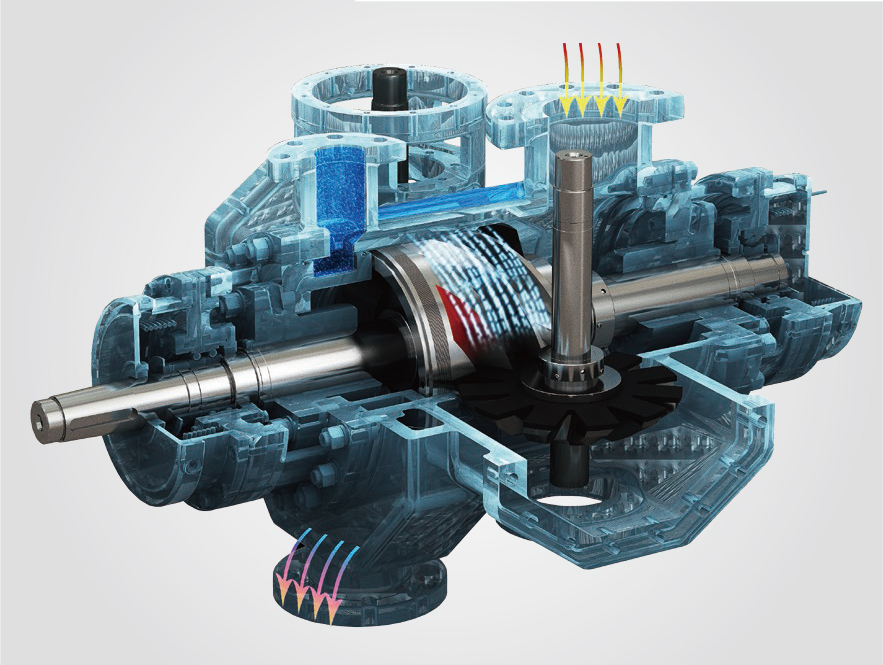

Working Principle

|

|

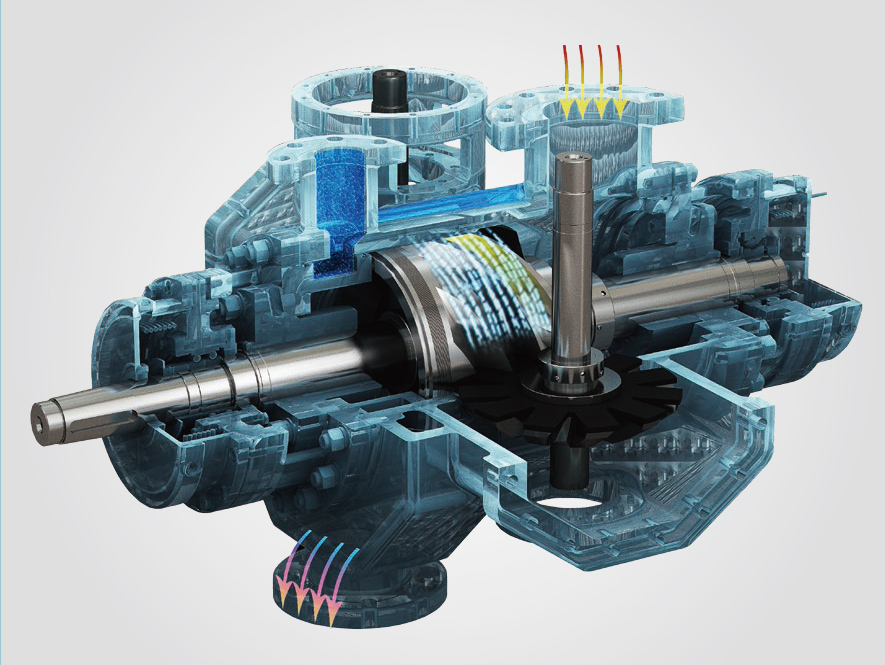

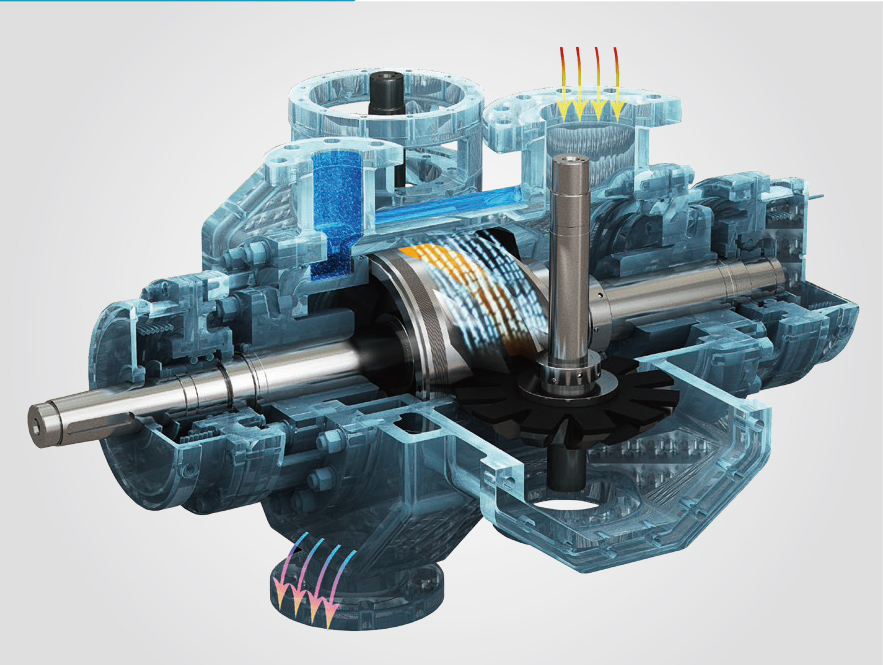

Inspiratory Process:

Spiral flute of the screw will be connected with the suction gas chamber before engaged, it is in suction condition. When the screw rotates in certain position, the star wheel will close the screw slot and form the working volume. At this time, the Inspiratory process is over.

|

|

|

Compression Process:

As screw rotates, the star wheel will moved forward along with the screw slot. Closed working volume is getting smaller. This process realizes the compression process. This process will create huge amount of heat. The cooling medium will be sprayed out to the surface and slots of the screw. At the same time when cooling medium takes away the heat, a thin film will be formed, serving both as sealing and lubrication. When the working volume is connected with the triangular vent hole, this process is over.

|

|

Discharge Process:

When the working displacement is connected with the triangular vent hole, as the rotor rotates, the compressed gas is transferred from discharge port to discharge chamber until the star wheel moves away from the slot, the discharge process is over.

|

HOMG advantages

|

|

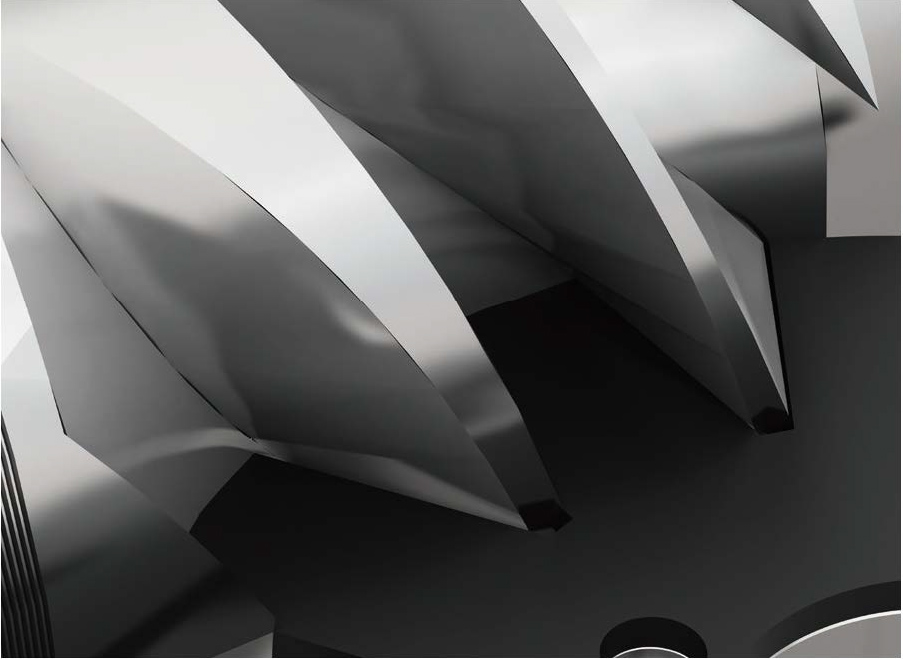

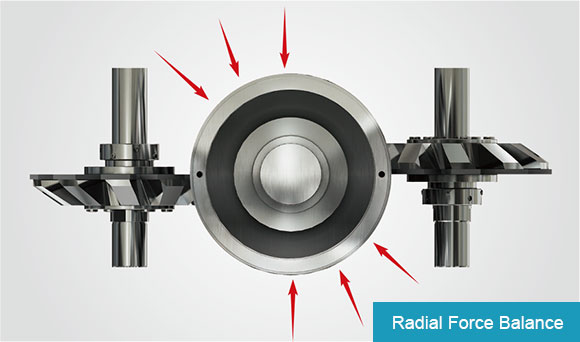

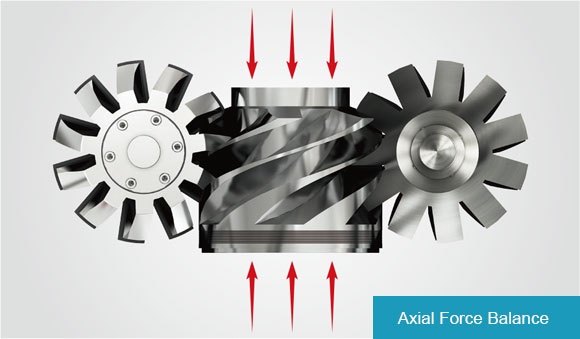

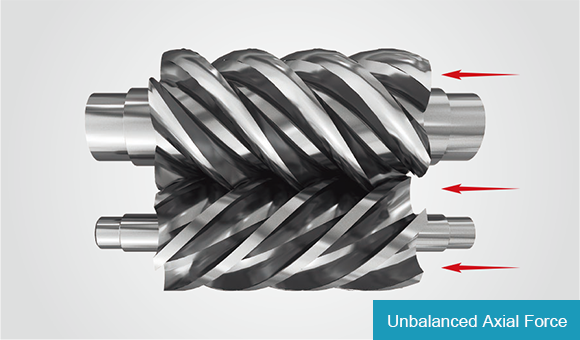

Engaged assembly consists of one singlescrew and two centrosymmetric star wheels

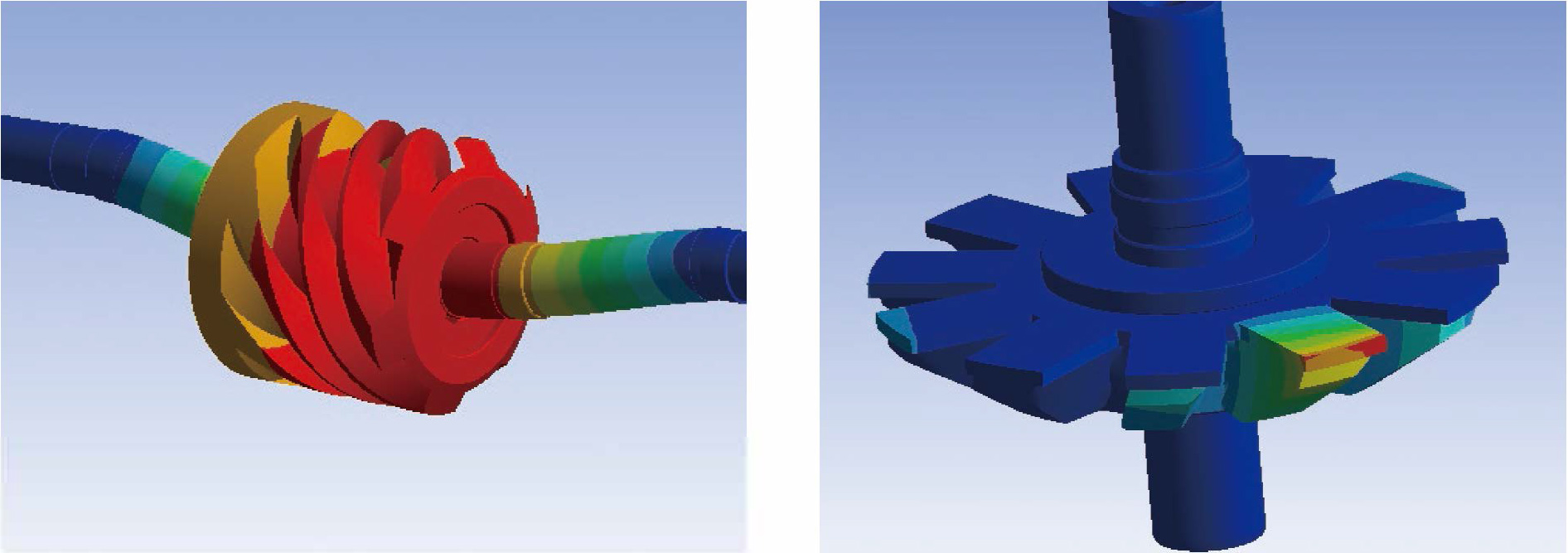

Haomi Power jointly developed the engaged structure with famous domestic university and acquired invention patents. By means of rotor dynamic analysis, FEA and thermodynamic analysis and fluid-solid coupling analysis, the reliable operation and aerodynamic and thermodynamic performance are guaranteed.

|

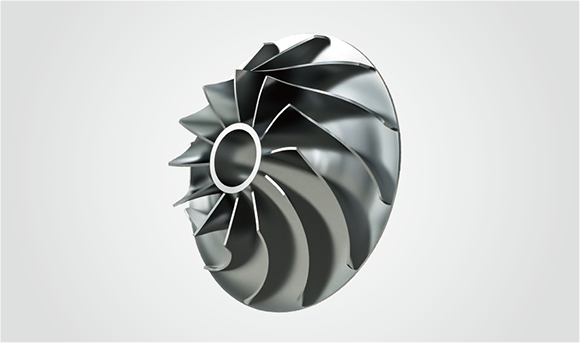

Star wheel-polyether-ether-ketone(PEEK) filled high tensile strength carbon fiber reinforced polymer

Excellent mechanical properties, anti-corrosion and auto lubricated. Haomi adopts unique metal lipping and modular cast star wheel, it improves the strength and rigidity, lowers the vibration and wear out risk.

|

|

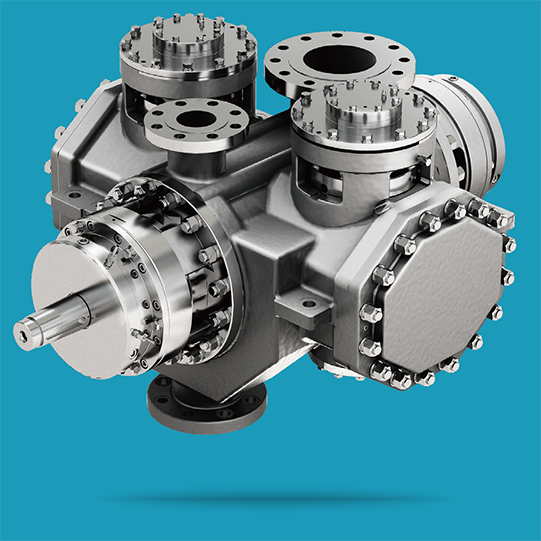

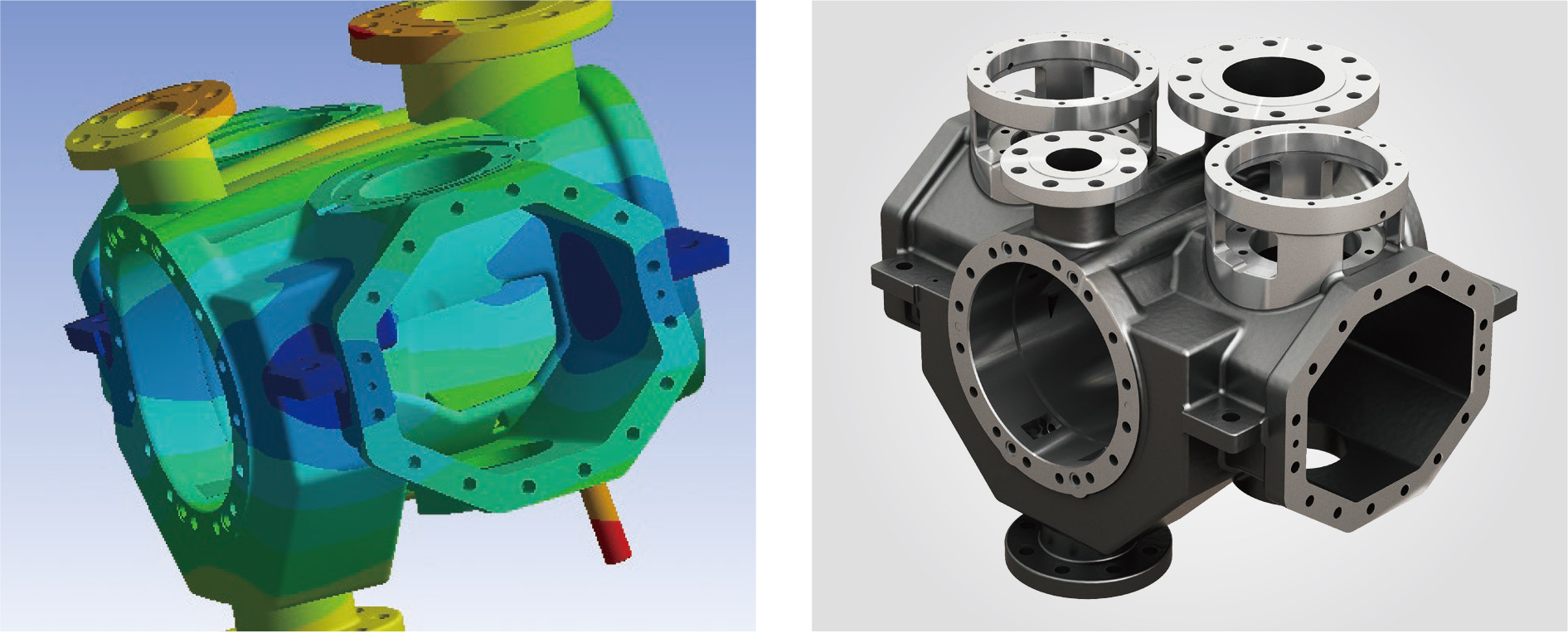

High tensile strength modular cast steel hull according to API 619 Standard

Pressure rating up to 70 Bar. High machining precision. Ensure correct positioning and engagement of screw and star wheels.

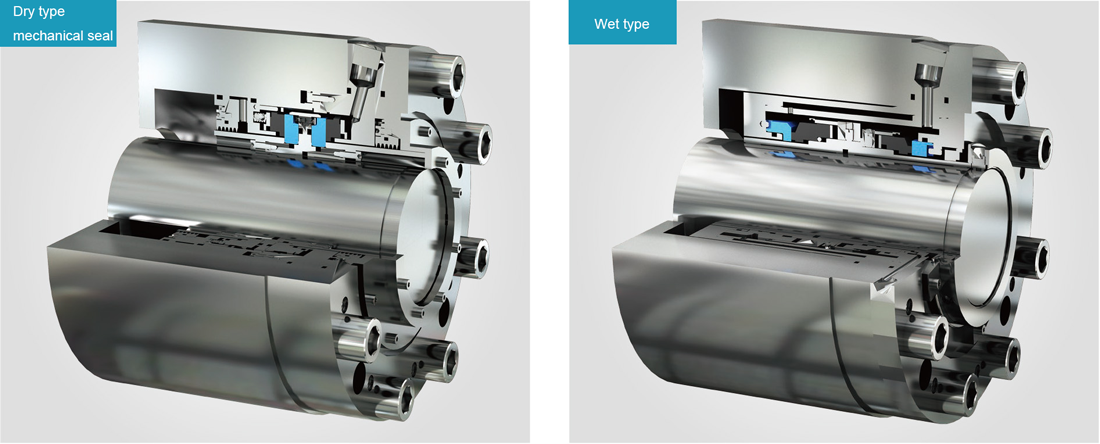

Haomi Group independently developed special mechanical seal for petrochemical process gas single-screw compressor according to API 682 standard.

Can be designed according to different process media, to meet the long cycle high reliable seal.

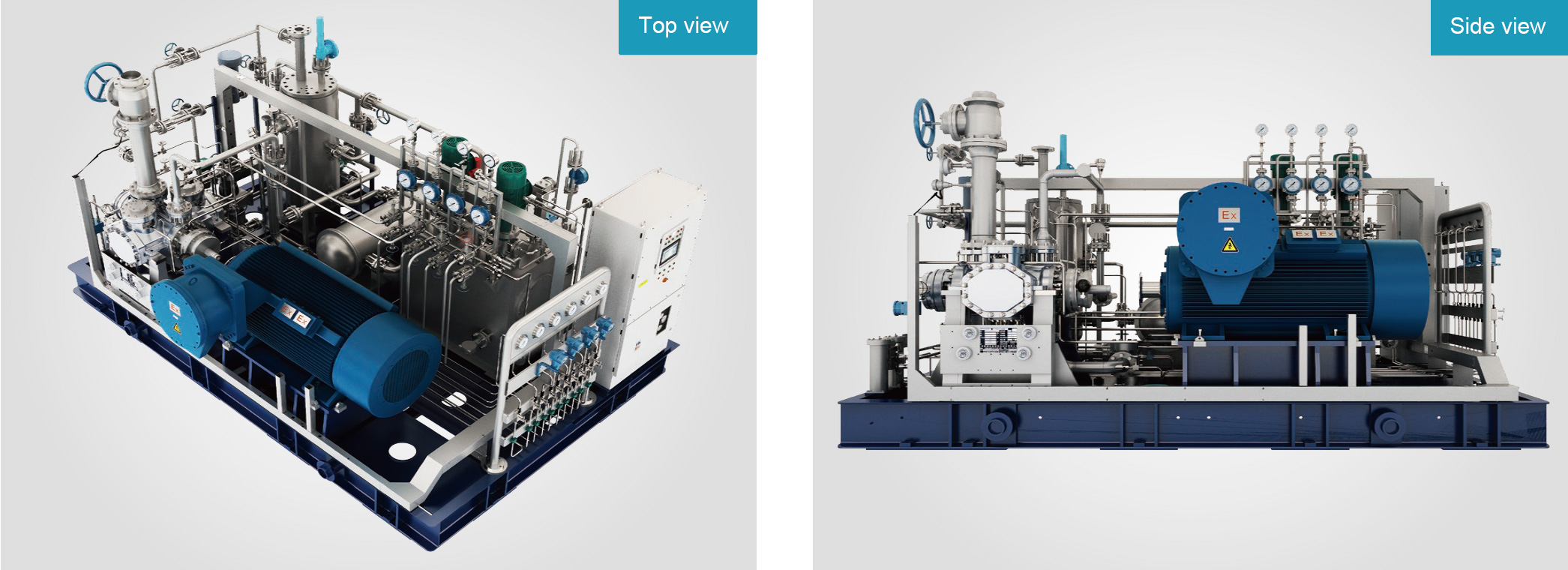

Skid mounted

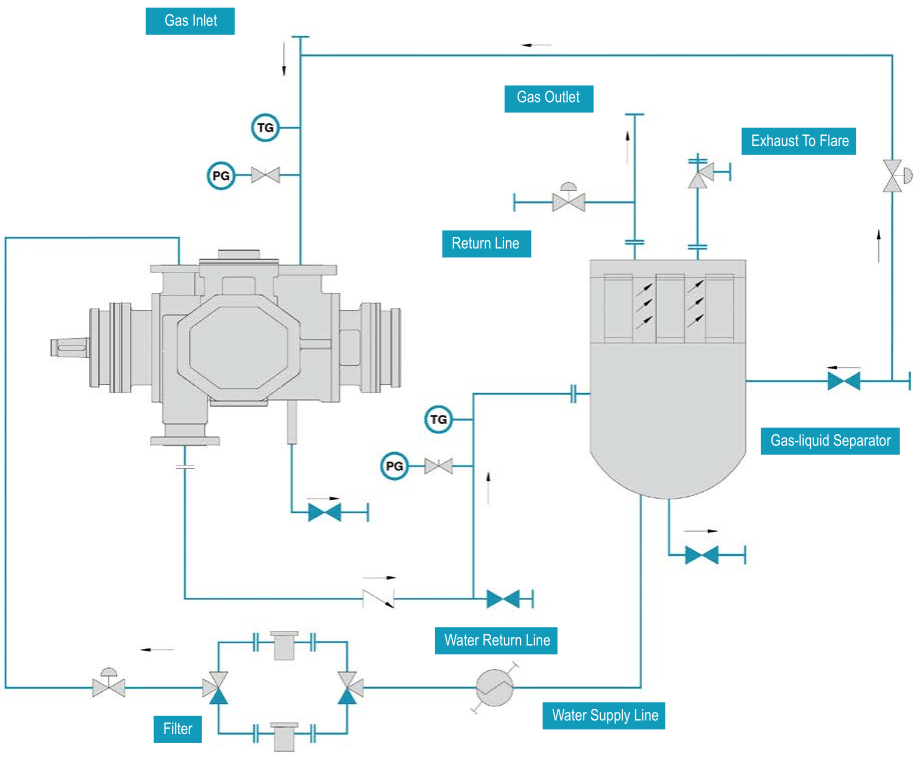

Main compressor, driver, gas-liquid Separator, sealing auxiliary system, gauge panels and control cabinet are integrated on the mounting skid. It has compact size and reasonable plan and saves installation space. It is convenient for installation and maintenance.

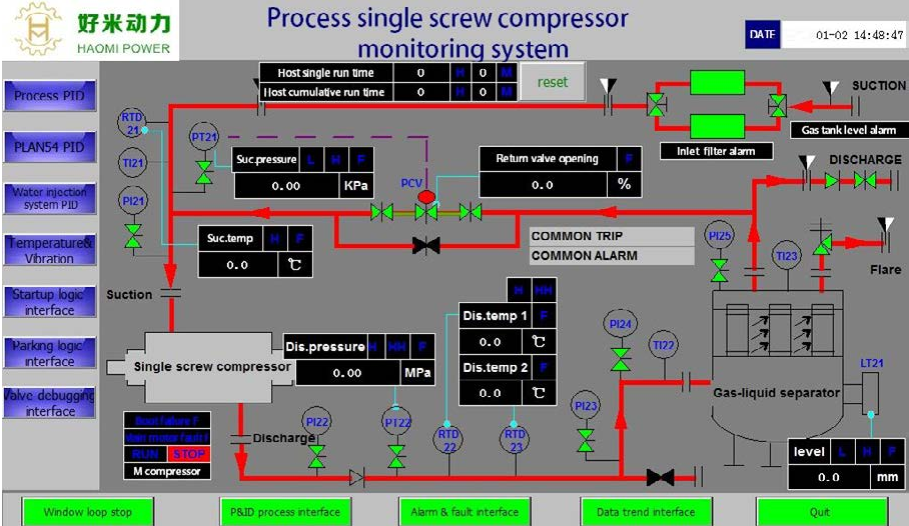

Intelligent PLC control system

This system can meet the process requirements of start/stop control of the compressor and interlock. It carries out real time remote monitoring of the pressure, temperature and vibration parameters, and it can establish data communication with User’s DCS system.

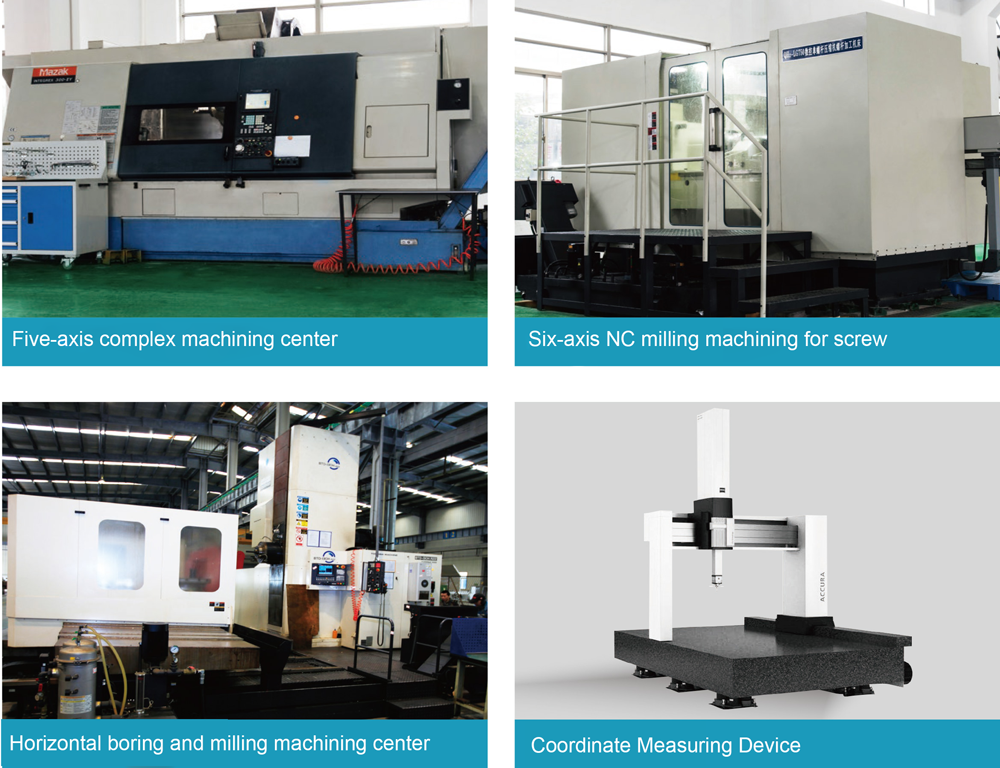

Materials and processing

| Material list of main parts | |

| Main parts | Material |

| Screw | Cr steel, 304(L), 316(L) |

| Star wheel | PEEK |

| Shaft | Cr steel, High tensile strength Alloy steel, Duplex |

| Housing | S.S. |

Note: Materials can be selected according to different working conditions.

Process and application

Note: This process is for reference only. Detailed design shall be based on actual requirement.

|

Propylene Gas Single-Screw Compressor application for one Sinopec company |

||||||||||||||